Editor’s note : This information is for historical purposes only. I have done what I can to update links found on this page (current as of April 2020) but 25 year-old e-mail addresses …. Really?

The following is a first draft of limited distribution, offered for comment. In further versions numerical indexing will be added and the document will be split into linked web pages. Thanks for your input.

+==oOo===+

High Performance Micro-Blimp (HPMB) Design Notes and Draft Narrative Specification

+==oOo===+

Original April, '96 post to LTA builders list -

Members of The Robot Group of Austin, Texas are building a video telepresence micro blimp capable of outdoor operation in a moderate breeze.

The aircraft will start with short "over the horizon" video/control communications range, later adding GPS and other micro avionics to the payload.

We have strong record in indoor radio control/robotic blimps and are seeking advisors and collaborators for the outdoor work.

The current spec. calls for an 18 foot blimp, with about four pounds of elective payload, capable of cruise at 12 knots or more.

One goal is to incorporate a balloonet/water ballast system to enable "high" altitude work. Another goal is to incorporate solar cells to extend missions. These are open projects to jump on.

Anyone who wants to mirror this project with their own construction and share technical resources is welcome. Contact david@robotgroup.org .

+==oOo===+

Honing the configuration -

Many folks' design/build experience, research, and flying experience went into the working concept for the HPMB. Several promising configurations and related design ideas were competitively assessed (by scoring matrix) for potential speed, maneuverability, reliability, and simplicity of construction.

A baseline for review was the classic airship design which is pendulum stable with nonvectored bilateral thrusters. Two other candidate designs incorporated vectored thrust; one was a typical twin vectored thrust design with rudder and elevator. Another was a futuristic neutrally balanced concept with tri-radially mounted vectored thrusters and no control surfaces.

The top dog, so far, is a Vee-Tailed Twin In-line Thruster design which scores high in every functional category. Its fast, agile, robust, and simple.

The dashing vee tail is an update on classical blimp tail design that reduces part count by a third, plus a surprise; a quality microblimp's vee-tail can be quickly adapted from off the shelf RC glider wings. Well known vee-tails include the Stealth Fighter and classic vee-tail Bonanza civil aircraft.

The In-line twin propulsion units, mounted just aft of center, provide as much balanced power as the blimp can carry. The advantages of this mounting approach, as popularized in the Lear Jet and DC-9, apply to blimps. In this case visualize a fat wingless vee tailed Lear Jet. This picture also resembles NASA's early lifting bodies leading to the space shuttle design. Twin electric propulsion offers vigorous yaw inputs allowing the vee-tail to be flattened in favor of pitch control. The degree of flattening is balanced against the urgent need for rudder steering in the case of a single propulsion unit failure.

+==oOo===+

Control Particulars -

Following common airship practice, this blimp will fly slightly heavy (~200-1000 grams) balanced and trimmed like a conventional (in this case semi-acrobatic) aircraft. This allows the aircraft to slowly glide down in the event of a propulsion loss, still controllable by the vee-tail. In the event of total control failure a heavy blimp comes down in due time, without sailing off to the next state.

Although the prop units are balance mounted in-line close to the

envelope's (horizontal) center of drag (and mass), the tail's drag causes the design to pitch up a bit when power is applied and the tail surfaces are centered. Trimming the tail down levels flight and some lift is scavenged, as in conventional aircraft. To balance pitch up maneuvering advantage, the pitch down position of the vee tail lightly interacts with prop wash, due to placement of prop unit and vee-tail.

To promote easy flying and allow emergency glide down, the design has a small amount of pendulum stability, balanced against a capability to loop and roll. In slightly heavy flight the vee-tail provides further roll stability due to its dihedral. Pendulum stability, general balance, propulsion and control surface placement will all be field tuned in test phases.

Loss of any one, two, or even three of the control surfaces or propulsion units results in proportional rather than total loss of control. A single tail foil allows feeble steering in glide mode and a single motor allows a curly cue course by timed throttle application.

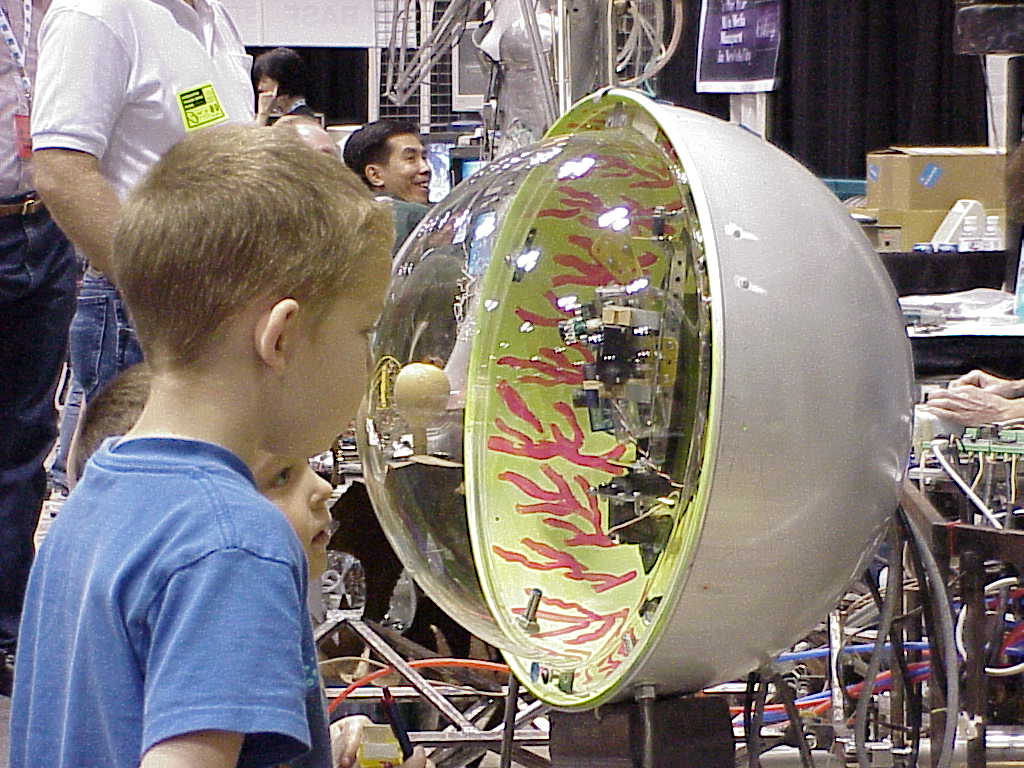

The flattened vee-tail imposes a coordinated roll/pitch turn technique much like the rudderless elevon design of the Flying Sphere prototype. Differential control of the propulsion units allows aggressive yaw turns. Modern RC gear allows for mixing and tuning standard pilot inputs to make unusual configurations intuitive to fly. A note on RC glider wing reuse for vee-tails- ...existing tab ailerons suffice for control at high speeds, but for close slow maneuvering rotating the entire wing is more effective. Ailerons can be frozen in place, used as trim tabs, or mechanically slaved to overall wing rotation to reduce stall.

+==oOo===+

Communications Architecture -

The big issue here is whether or how to multiplex various high and low bandwidth data streams.

Some assumptions can be made -

-Use of RC control frequencies and protocols

-High Bandwidth Video/audio and sensor telemetry.

-Emergency Locator Beacon - a high intensity pulse useful for orienting narrow angle antennas and locating the blimp in case of a total mission failure.

-Antenna Garden - A combination of highly directional and omnidirectional switchable antennas is proposed.

===included comment from Mark C. Otto===

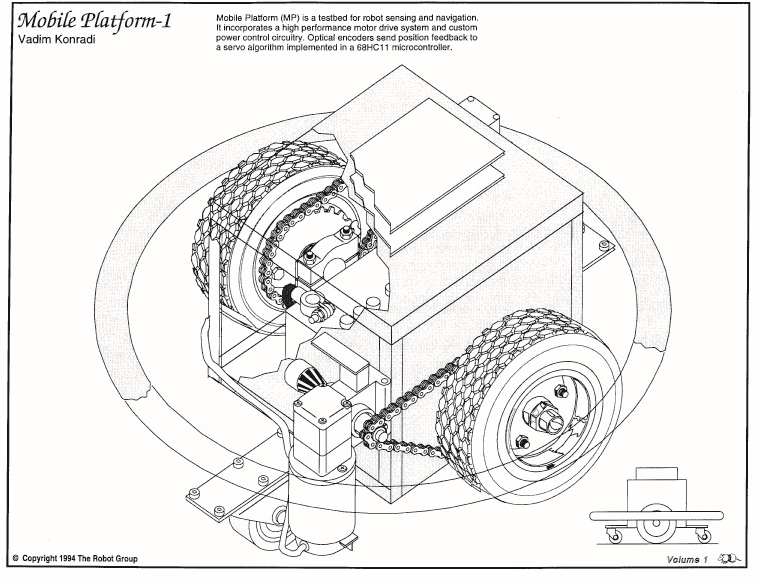

I have recently designed a telemetry system for use on my R/C airplanes that uses a 68HC11 and SuperCircuits ATV transmitter. The audio channel is driven by a modem chip off the HC11's serial port so I get full motion video and 1200 baud data on the audio. A modem on the audio output of the TV receiver feeds my HP palmtop with the data at RS232 levels and the palmtop stores it on flash disk. My only regret is that I didn't go with PC

electronics for my transmitter - the lack of a sync pulse stretcher on the SuperCircuits transmitter prevents sufficient sync signal integrity to drive a VCR from the recovered video.

+==oOo===+

Avionics Suite -

GPS - Provides superior positioning info for "over the horizon" work. Can be integrated to GIS, etc.

Flux Gate Compass - Backs up GPS and provides pointing info if blimp is crabbing or yawing in place.

Two axis inclinometer - Provides attitude info in aerobatics.

Thermistor - temperature reading.

+==oOo===+

MicroVideo Components -

Current cam of choice is the PC-17 Color Microvideo Camera available thru Supercircuits. Its a 2.5 ounce, 450 line, 2"cube.

Supercircuits also offers a transmitter suitable for initial flights, the 915 MHz ATV-900 (is this the model that Otto says suffers from the lack of a sync pulse stretcher?).

+==oOo===+

Altitude Control -

As a rough goal, the design's lifting volume with proper altitude control gear should allow operation in excess of 3000 meters (stretched envelope if needed).

Balloonet system - Keeps blimp envelope taut at lower altitudes and enables climbing without venting helium. Sub issues: a) maintaining a constant relative pressure in the envelope. A photo or micro switch tensiometer mounted on the envelope could sense flaccidity and trigger air pump. and b) selecting a lightweight air pump to pressurize the balloonet. In one approach a ram air inlet may assist a fan pump. In another scheme a small piston pump or motorized "campers air mattress" pump provides the pressure. c) Size of balloonet up to about a third of total gas volume.

Drop Ballast System - Allows blimp to lighten for maneuvering or to balance helium loss, rain/ice/payload pickup. Plain water entails freeze risk. Other options include powder or mealy media or antifreeze liquids.

Frost proofing - Low temperatures could affect electronics and embrittle materials.

+==oOo===+

Propulsion -

Two Graupner 400 motors with Olympus 2.3/1 reduction gears and between 8

and 12 inch props, size subject to tuning are being used. Such components are being specified with the help of electric airplane racing guru, George Parks and Wolf of American Angler and RC Hobby of Austin. A reduction gear and large prop operate more efficiently at low speeds and high altitudes than a small prop with no reduction gear.

Positioning - The small new human carrying Hornet blimp shares inline positioning of propulsion units.

Solar Power - 2-3 sq. meters of solar film or cells could generate nearly 100 watts of power for endurance missions. Amorphous solar films in on-hand catalogs are rather heavy for their power density. Crystalline cells are fragile, expensive, and laborious to install. Better solutions are sought.

===include message excerpt from David Beck===

Perhaps there is a way that the shape of the blimp could be adapted to

focus the sun on an array in the center of the blimp. That is, perhaps the

part facing up would be clear, and the lower part would be reflective. In the center of your tube, you could suspend an array at the focus point. This would keep the array weight down, yet still generate lots of power.

Also it would protect the array, and with the money saved on buying lots of

cells, you could buy a few more efficient cells. You'd generate a lot of heat at that point, so you don't want to collect too much sun, but on the

other hand, the heat generated could be used to generate additional lift - so maybe you'd want a series of tubes, and make a structure kind of like an

inflatable mat.

===end included message===

Comment - The idea of a suspended solar array under a transparent envelope window may allow for optimal tilting to solar incidence independent of the airship's roll axis. The reflective trough idea is appealing as a means of minimizing cell count. Suspending a reflective sheet in the bag would result in a near optimal catenary shape. Unfortunately the lower refractive index of lifting gas means it can't be used as a focusing lens in a convex profile.

Batteries - The latest mainstream battery technology affordable by the project will be utilized, although Ni-cads are operationally acceptable for some missions.

+==oOo===+

Envelope and Hardpoints -

A big issue is using the Mylar gas bag as the primary envelope vs. as a liner for a fabric outer skin. At this point a naked Mylar bag with tape reinforcement will be used and later upgraded as it proves inadequate. This approach will save weight, cost, and complexity in trade off with durability.

Hardpoints are rigid foam structures supporting motors, tail foils, electronics, and batteries. Stress relieving tapered stringers radiate from the hard points and attach to "crow foot" reinforced anchor points on the envelope.

+==oOo===+

Vee-Tail Construction Note -

While slight deflections of small control surface areas suffice for cruising speed maneuvers, large areas and aggressive deflections are needed for good slow speed agility. A large area/deflection approach requires special care in designing large, strong, and light articulated mountings. An oversized elevon mounted on a tapered strake is the elected layout to make these trade-offs.

+==oOo===+

Rain Proofing -

Operation in wet weather adds weight and threatens electronics.

Electronics bays are to be modestly weather proofed similarly to autos using gravity gutters and gaskets while maintaining ease of access. Loops and rolls in rain are proscribed. Drop ballast should offset modest rain/snow/ice loads. Outer envelope material should be hydrophobic (like Scotch Guard), if not waterproof, without adding much weight from fabric treatment.

Electronics and other sensitive components are to be housed in insulated enclosures. Electronic waste heat may suffice to inhibit condensation. Silica packs could help. Ram air venting might be useful if the electronic bays are too well insulated for hot weather operation.

+==oOo===+

Test Flights / Mission Profiles -

Benchmarking - Speed, climb, lift, endurance, etc. would be established in early flights.

Cross Country - Following prevailing winds and conserving propulsion for course adjustment and landing.

High Altitude - Stripping all excess payload, the high altitude capability of the design will be tested.

Sample Pickup - Touch down on (calm) water to acquire samples for biological and chemical analysis.

Exploration in close environments - Urban and rural canyons, building interiors and other crowded locations put a premium on agility.

Station Keeping - Maintaining a constant position for as long as resources allow. Useful in comm relay work and observation. GPS automation a goal.

Robotic Operation - Testing of computer based autonomous control schemes.

Public Events - Ideas range from carrying a tiny video projector that displays thru the envelope, a la Bladerunner, to a "fire blimp" that tows pyrotechnics displays.

Ultimate missions - a) Search and rescue b) Hostile environments such as volcanoes and storms c) New RC Solar Challenger Blimp race (in parallel with Solar Challenger car race in Australia) d) New records for flight in the RP/A-LTA class d) Teletourism in farflung lands

+==oOo===+

E-mail list for this project (don't spam this list unless post is of

high interest to *both* LTA and Robotics folks) -

(Mark C. Otto) mco@hprtws13.ptp.hp.com,

(Martin J. Maxwell) maxwell@goodnet.com,

robot-group@cs.utexas.edu,

(John Piri) jpiri@ridgecrest.ca.us,

(Prof. John Canny) jfc@CS.Berkeley.edu,

(Reuben J. Hoggett) RHoggett@vitgcprm.telecom.com.au,

(Capt. David Guinn) QUINTI@aol.com,

(David Santos) david@robotgroup.org,

(Dave Beck) dbeck@execpc.com

+==oOo===+

Variants -

The basic design can be varied to achieve top performance in specialized missions.

Speed and endurance missions would benefit from a stretched envelope offering extra lift for bigger motors and/or more batteries.

Absolute speed records will require gas engines.

Indoor acrobatic models should have shorter fatter gas bags and bigger control surfaces for turning ease.

A stripped down low cost version would be popular even without all the fancy high-altitude all-weather solar-boosted fully-instrumented features.

+==oOo===+

Autonomous Flight -

Several approaches are of interest. One is to integrate GPS/GIS based cross country navigation by an agent such as AirSoar. Another tack is to do local exploration based on interpretation of proximity sensor data. A third approach is complex mission level behavior as in Orca, the top level intelligence in the MSEL EAVE architecture. (See URLs section for links to above)

Ultimate integration of the various schemes would allow varied missions with intelligent response to dynamic local changes within an absolute navigation framework.

+==oOo===+

Rapid Response -

For some applications, such as search and rescue, a rapid response blimp system is required. This aspect may long remain at the concept phase, but has interesting challenges. Obviously an inflated blimp taking up a lot of space and constantly losing helium is not good in a low usage rapid response mission unless instant operation is needed. A better solution is a suitcase sized package that stays charged and self-inflates and takes off automatically. Waiting for a volcanic eruption is a cool application idea.

+==oOo===+

Legal and Safety Issues -

A comprehensive set of safety features and operational policies shall govern the use of the airship.

Prop hazard - Props will be orange tipped and have a piano wire hoop to guard against contact with people and objects. Prop operation will only occur away from close proximity of third parties.

Plummeting hazard - All components of the blimp will be tied together. All high density components will be mounted on low density structures as shielding. Total loss of lift should result in a drop speed of no more than 30 mph.

Fire Hazard - No combustible fuels or ignition sources will be carried in normal use.

Navigation hazard - About half our team members are pilots and understand the regulations and issues involved. (most senior pilot/consultant is a 747 captain for United, others are already flying HTA RPV's under govt. contract)

Great care will be taken to follow applicable aviation law and best safety practice with this project.

+==oOo===+

Related URLs -

A preliminary page exists for this project, but contains nothing not

found in this document. Stay tuned for a hot concept rendering and

configuration sketches, plus updated specification info -

http://www.polycosmos.org/ROBOTGRP/ROBOBLMP/CMDRSALM.HTM

(archived at the Internet Archive)

Dr. John Canny's net blimps (Space Browsers) telefloat beyond the

surly bonds of earth -

http://vive.cs.berkeley.edu/blimp/

(archived at the Internet Archive)

Supercircuits is the project's micro video supplier. If you haven't

seen their catalog you'll flip out when you do -

http://www.scx.com/supercircuits.html

West Coast Blimps is worth checking out for envelope materials and

other products -

http://www1.ridgecrest.ca.us/~jpiri/

(archived at the Internet Archive)

The UK Hornet Blimp is an advanced design that shares some

performance features with Capt. Salamander -

http://www.fast-lanes.com/Hybrid/Advanced_Hybrid_Air.html

(dead link, not archived at the Internet Archive)

Air-Soar is a good example of an autonomous flight agent -

http://krusty.eecs.umich.edu/air-soar/

(archived at the Internet Archive)

Underwater robots share many control and mission characteristics with

airships -

http://pha.cs.unh.edu/MSEL/architecture.html

(dead link, not archived at the Internet Archive)

+==oOo===+

Work to date -

-Project documentation undertaken in draft.

-Blimp envelope builder's instructions written for web.

-Provision of Mylar and assistance to Dr. Canny, Berkeley CS, and Brooks Coleman.

-Propulsion consultation with electric airplane guru, George Parks.

-Eight microblimp related pages created.

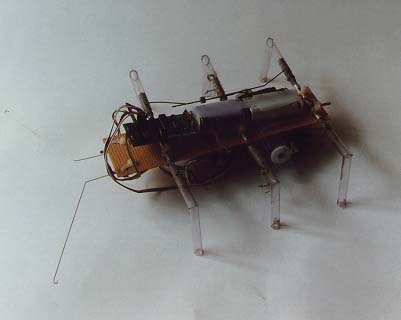

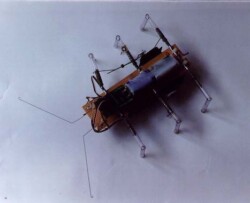

-Construction begun on Propulsion Nacelles.

-Research progress on various fronts; physical configuration, video/control communications, balloonet/water ballast altitude control, propulsion, avionics, etc..

-Mark IV envelope reallocated to helilifter blimp. HPMB to have new

envelope.

The Captain Salamander name derives from a local (Austin,Texas) biologist's (Jim Collett) concept for a Barton Creek water quality inspection blimp.

Generic Intellectual Property Statement - Free noncommercial personal and educational use encouraged. dave@faustex.com

Want to build a micro-blimp? Instructions on fabricating envelopes are available.

Comment to webmaster@faustex.com